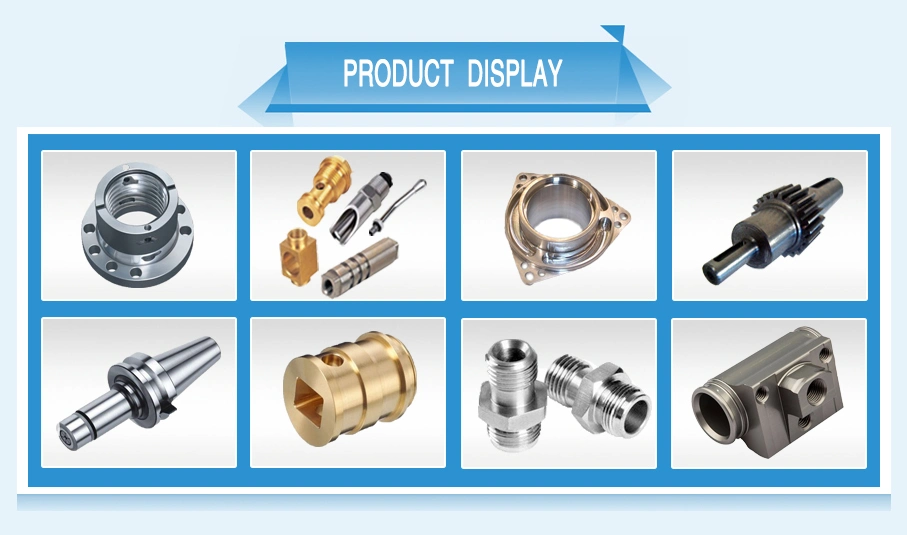

OEM Precision Metal/Brass/Alloy Machining for C3604 C1100 Material Brass Copper Bronze CNC Machining

OEM/Metal processing auto parts

CNC machining parts

We are a professional manufacturer which can provide you with various techniques of machining parts strictly according to your drawings or specific requirements.

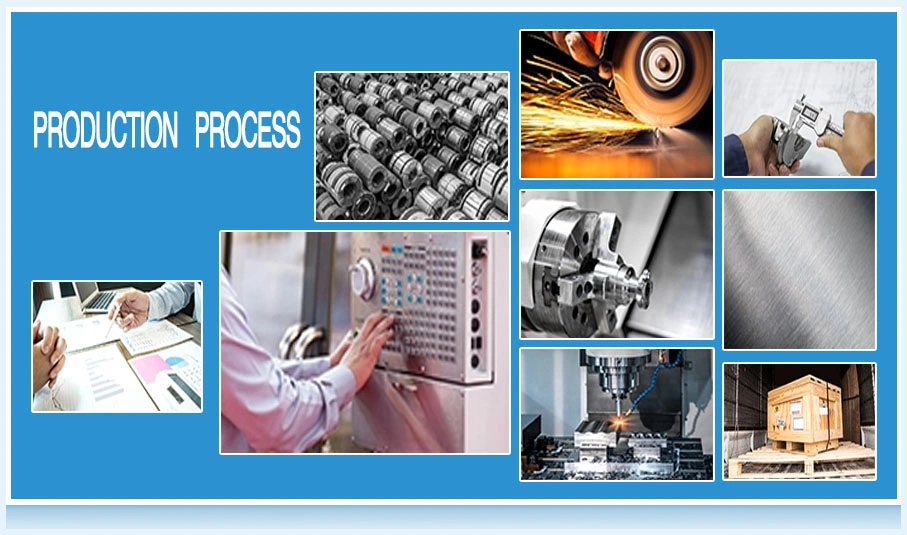

CNC machining department:

professional of the CNC machining designed precision parts, with processing one-stop services. Materials, valet design and strong technology are all belongs to our key advantages.

Workshop equipment:

CNC turning lathe, Grinding machine, Milling Machine, CNC machining center, Spark machine, cutting-off machine, card punch, EDM Machine, Wire-Cutting Machine, and some other normal processing machineries.

Post processing machine: Drill machine, multipoint drill machine, Dull polish machine, Polishing machine, Slinging machine, Cylinder processing machine, lapping machine, punching, and baking finish equipment.

Production range

Including: auto&motocycle, mining machinery, building industry, electrical and electronic products, industrial machinery and equipment, transportation, and etc.

Authentication

We passed the ISO 9001-2000 International Quality System

1, Accuracy: according to the dimension tolerance of machining of customers' requirement.

2, Surface roughness: Ra 0.8-3.2

3, Weight: ranging from 0.50g to 10,000kg

4, Surface finish: polishing, oiled(rust-prevented), zinc-plated, chrome-plated, hot-galvanized, sandblasting, painting, powder-coasting.

Inspection:

Inspection: in-house and third party

All the products are strictly inspected by operator and skilled QC with record put down.

Universal inspection tools: hardness tester, Height ruler, Depth ruler, Outside ruler, Venire Caliper,etc.

Best service:

1, Good communication with every of our customer, especially willing to discuss the details of your drawings.

2, On time delivery to guarantee.

3, High quality with a reasonable price.

Specifications

cnc parts

Material:steel

Surface:mirror polishing

cnc parts

Material: steel

Process: cnc machining

Surface: mirror polishing

OEM & small orders are welcome

Inspection report and material certificate are available upon request.

customer's drawings are accepted

Minimum order: according to customers' requirements.

Sample: sample for free, but you should pay for the express fee for the samples.

Delivery date:

1 Making the moulds within 10-15 days after receive the 30% payment in advance.

2 The first container is delivered within 10-15 days after the sample is eligibled.

Packing size: according to the products' size and quantity.

1. Metal machining parts strictly according to customer's drawing, packing and quality request; <o: P>

2. Tolerance: Can be kept in +/-0.01mm; <o: P>

3. The most advanced CMM inspector to ensure the quality; <o: P>

4. Experienced technology engineers and well trained workers; <o: P>

5. Fast and timely delivery. Speedily&professional service; <o: P>

6. Give customer professional suggestion while in the process of customer designing to save costs. Our freight price is often 30-50% lower than customer's; <o: P>

7. Customers can use PAYPAL and other online payment platform to pay a small amount of sample fee to shorten the sample production time; <o: P>

8. Quality assurance in accordance with ISO9001: 2008.

Our products have been exported to Japan, Unite States, South Korea and Europe for almost seven years.

Our leading products are a variety of models and specification of ball valves, pipe fitting's parts, meters'parts, flow meters' parts, surface treatment and so on.

We can support sample avaliable and we have OEM manufacture exprience for seven years.

Service Principles: Cheap, Efficient and Customer-oriented

Processing Method: Custom medical precision parts high demand parts precision machining hardware

Cnc machining, turning, milling, drilling, grinding, broaching, welding and assembly.

Packgage: Custom medical precision parts high demand parts precision machining hardware

Suitable for sea and air transportation or as required

Custom medical precision parts high demand parts precision machining hardware

1. Q: Why choose Shengao product?

A: We shengao have our own plant-- Weifang Shengao machinery Co.,Ltd, therefore, we can surely promise the quality of every product and provide you comparable price.

2. Q: Do you provide OEM Service?

A: Yes, we provide OEM Service.

3. Q: Do you provide customized forging products?

A: Yes. Customers give us drawings and specifications, and we will manufact accordingly.

4. Q: What is your payment term?

A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

OEM/Metal processing auto parts

CNC machining parts

We are a professional manufacturer which can provide you with various techniques of machining parts strictly according to your drawings or specific requirements.

CNC machining department:

professional of the CNC machining designed precision parts, with processing one-stop services. Materials, valet design and strong technology are all belongs to our key advantages.

Workshop equipment:

CNC turning lathe, Grinding machine, Milling Machine, CNC machining center, Spark machine, cutting-off machine, card punch, EDM Machine, Wire-Cutting Machine, and some other normal processing machineries.

Post processing machine: Drill machine, multipoint drill machine, Dull polish machine, Polishing machine, Slinging machine, Cylinder processing machine, lapping machine, punching, and baking finish equipment.

Production range

Including: auto&motocycle, mining machinery, building industry, electrical and electronic products, industrial machinery and equipment, transportation, and etc.

Authentication

We passed the ISO 9001-2000 International Quality System

1, Accuracy: according to the dimension tolerance of machining of customers' requirement.

2, Surface roughness: Ra 0.8-3.2

3, Weight: ranging from 0.50g to 10,000kg

4, Surface finish: polishing, oiled(rust-prevented), zinc-plated, chrome-plated, hot-galvanized, sandblasting, painting, powder-coasting.

Inspection:

Inspection: in-house and third party

All the products are strictly inspected by operator and skilled QC with record put down.

Universal inspection tools: hardness tester, Height ruler, Depth ruler, Outside ruler, Venire Caliper,etc.

Best service:

1, Good communication with every of our customer, especially willing to discuss the details of your drawings.

2, On time delivery to guarantee.

3, High quality with a reasonable price.

Specifications

cnc parts

Material:steel

Surface:mirror polishing

cnc parts

Material: steel

Process: cnc machining

Surface: mirror polishing

OEM & small orders are welcome

Inspection report and material certificate are available upon request.

customer's drawings are accepted

Minimum order: according to customers' requirements.

Sample: sample for free, but you should pay for the express fee for the samples.

Delivery date:

1 Making the moulds within 10-15 days after receive the 30% payment in advance.

2 The first container is delivered within 10-15 days after the sample is eligibled.

Packing size: according to the products' size and quantity.

1. Metal machining parts strictly according to customer's drawing, packing and quality request; <o: P>

2. Tolerance: Can be kept in +/-0.01mm; <o: P>

3. The most advanced CMM inspector to ensure the quality; <o: P>

4. Experienced technology engineers and well trained workers; <o: P>

5. Fast and timely delivery. Speedily&professional service; <o: P>

6. Give customer professional suggestion while in the process of customer designing to save costs. Our freight price is often 30-50% lower than customer's; <o: P>

7. Customers can use PAYPAL and other online payment platform to pay a small amount of sample fee to shorten the sample production time; <o: P>

8. Quality assurance in accordance with ISO9001: 2008.

Our products have been exported to Japan, Unite States, South Korea and Europe for almost seven years.

Our leading products are a variety of models and specification of ball valves, pipe fitting's parts, meters'parts, flow meters' parts, surface treatment and so on.

We can support sample avaliable and we have OEM manufacture exprience for seven years.

Service Principles: Cheap, Efficient and Customer-oriented

Processing Method: Custom medical precision parts high demand parts precision machining hardware

Cnc machining, turning, milling, drilling, grinding, broaching, welding and assembly.

Packgage: Custom medical precision parts high demand parts precision machining hardware

Suitable for sea and air transportation or as required

Custom medical precision parts high demand parts precision machining hardware

| Material | Rough Process | Service we provide | Surface treatment | Equipment List |

| Aluminum 6061/6063/7075 | Die Casting | CNC Machining | Colored Anodize | CNC Milling Machine |

| ADC12 | Aluminum extrusion | Turning, Milling | Sand Blast | CNC Lathe Machine |

| ZZnAl4-1 | Forged | Sheet Metal Fabrication | Electrical Polish | Grinding Machine |

| Stainless Steel 304/314/316 | Invest Casting | Welding, Stamping | Zinc/Nickel/Chrome Plate | Drilling Machine |

| Steel/Carbon Steel | Powder metallurgy | Punching, Drilling | Epoxy Powdering Coat | Polishing Machine |

| Brass/Copper/Bronze | Plastic injection | Grinding, Polishing | Blacken | Bending Machine |

| Plastic | Anodizing, Coating | Water transfer | Welding Machine | |

| Customer request | Customer request | Assembling | Customer request | Wire-cutting |

| Custom OEM Service | Laser-cutting | |||

| Water cutti |

1. Q: Why choose Shengao product?

A: We shengao have our own plant-- Weifang Shengao machinery Co.,Ltd, therefore, we can surely promise the quality of every product and provide you comparable price.

2. Q: Do you provide OEM Service?

A: Yes, we provide OEM Service.

3. Q: Do you provide customized forging products?

A: Yes. Customers give us drawings and specifications, and we will manufact accordingly.

4. Q: What is your payment term?

A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.