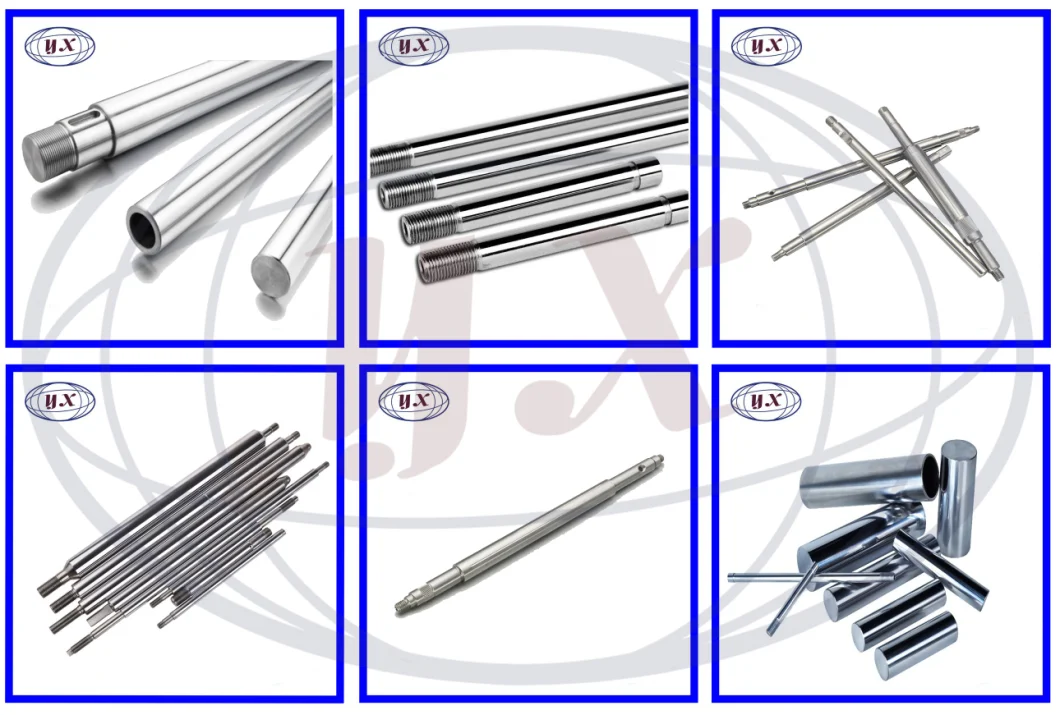

Product Description:

Manufacturing Main Process description:

1. Hydraulic Steel Raw Material Cutting

2. CNC Machining & additional broaching and milling operations

3. Induction Hardening & Grinding

4. Chrome Plating

5. Dehydrogenation and Tempering

6. Polish and Superfinish Polish

7. 100% Inspection

8. Craft Boxes and Wooden Case Packaging

Our advantage:

* One-Sotp service(from design to mass production)

* OEM /ODM Customized services

* Rapid prototyping & low-volume production

* High quality & low prices

* Highly skilled manufacturing process.

* Strict quality Control System.

Our promise:

* The delivery time and the package can be controled according to the customers' requirement completely.

* we will produce the products seriously according to the drawings, and make sure all the products is suitable for the custoners.

* We will communicate with the customers all the time about the products, we will send the pictures to the customers, so that they can know the Processing process

Our Policy:

Innovation and developing in Technique

High level of expertise

Outstanding quality

On-time delivery to customer needs

FAQ:

1. Are you a factory or a trading company?

A: We are a factory which has been specialized in cnc machining & automatic manufacturing for more than 13 years.

2. Where is your factory and how can I visit it?

A: Our factory is located in Qingdao city and you can get more detailed information by browing our website: http://qdyinxiao.en.made-in-china.com or Visit us in person.

3. How long can I get some samples for checking and what about the price?

A: Normaly samples will be done within 3-7 days (automatic machining parts) or 7-10 days (cnc machining parts). The sample cost depends on all information (size, material, finish, etc.). We will return the sample cost if your quantity is good.

4. How is the warranty of the products quality control?

A: We hold the tightend quality controlling from very begining to the end and aim at 100% error free.

| Outer Diameter | Ø 6mm-1200mm |

| Total Length | 100mm -10000mm |

| Material | DIN CK45,SAE1045,S45C,SAE1026,ST52,20MnV6,42CrMo4,40Cr,AISI304/316/431 |

| Chrome Thickness | 10~25 μm |

| Chrome Hardness | 60 HRC Min |

| Roughness | Ra 0.2 Micron Max |

| Straightness | 0.2/1000mm |

| Yield Strength | According to the steel material and customer requirement |

| Tensile Strength | According to the steel material and customer requirement |

| Elongation | According to the steel materia |

| Bend Test | According to customer requirement |

| Supply condition | 1. Hard Chrome Plated 2. Induction Hardened 3. Dehydrogenation & Tempered |

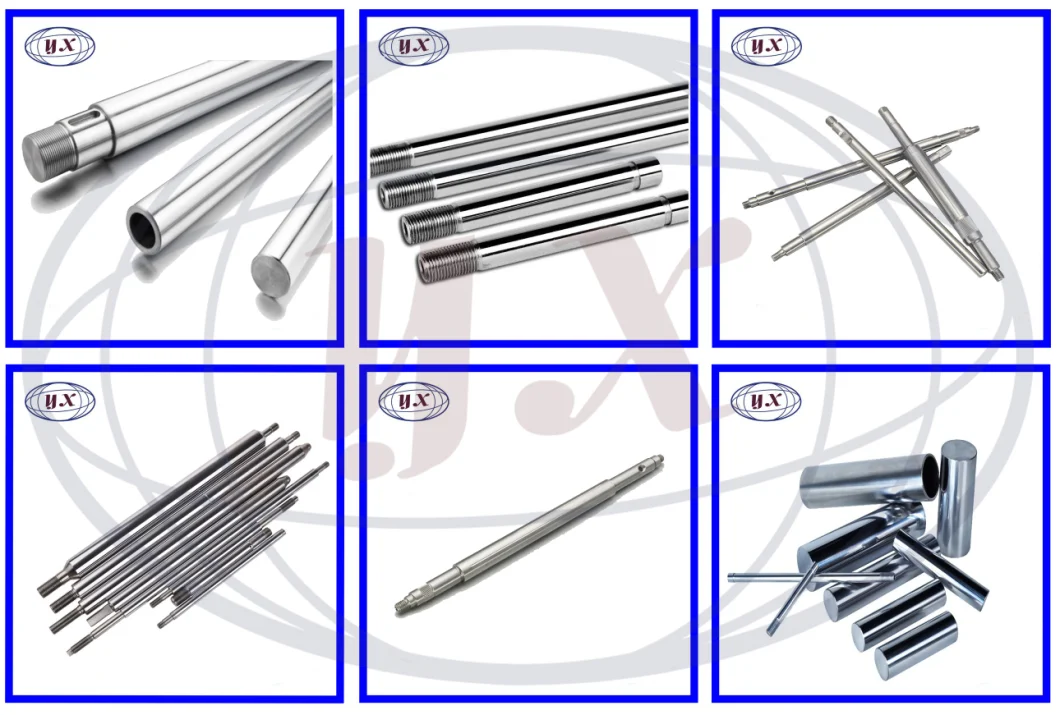

Manufacturing Main Process description:

1. Hydraulic Steel Raw Material Cutting

2. CNC Machining & additional broaching and milling operations

3. Induction Hardening & Grinding

4. Chrome Plating

5. Dehydrogenation and Tempering

6. Polish and Superfinish Polish

7. 100% Inspection

8. Craft Boxes and Wooden Case Packaging

Our advantage:

* One-Sotp service(from design to mass production)

* OEM /ODM Customized services

* Rapid prototyping & low-volume production

* High quality & low prices

* Highly skilled manufacturing process.

* Strict quality Control System.

Our promise:

* The delivery time and the package can be controled according to the customers' requirement completely.

* we will produce the products seriously according to the drawings, and make sure all the products is suitable for the custoners.

* We will communicate with the customers all the time about the products, we will send the pictures to the customers, so that they can know the Processing process

Our Policy:

Innovation and developing in Technique

High level of expertise

Outstanding quality

On-time delivery to customer needs

FAQ:

1. Are you a factory or a trading company?

A: We are a factory which has been specialized in cnc machining & automatic manufacturing for more than 13 years.

2. Where is your factory and how can I visit it?

A: Our factory is located in Qingdao city and you can get more detailed information by browing our website: http://qdyinxiao.en.made-in-china.com or Visit us in person.

3. How long can I get some samples for checking and what about the price?

A: Normaly samples will be done within 3-7 days (automatic machining parts) or 7-10 days (cnc machining parts). The sample cost depends on all information (size, material, finish, etc.). We will return the sample cost if your quantity is good.

4. How is the warranty of the products quality control?

A: We hold the tightend quality controlling from very begining to the end and aim at 100% error free.