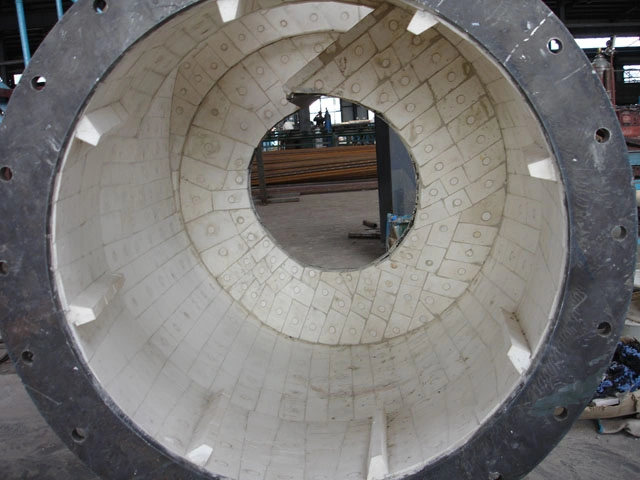

Aluminum Oxide Ceramic Lined Equipment for Mining

Product Description

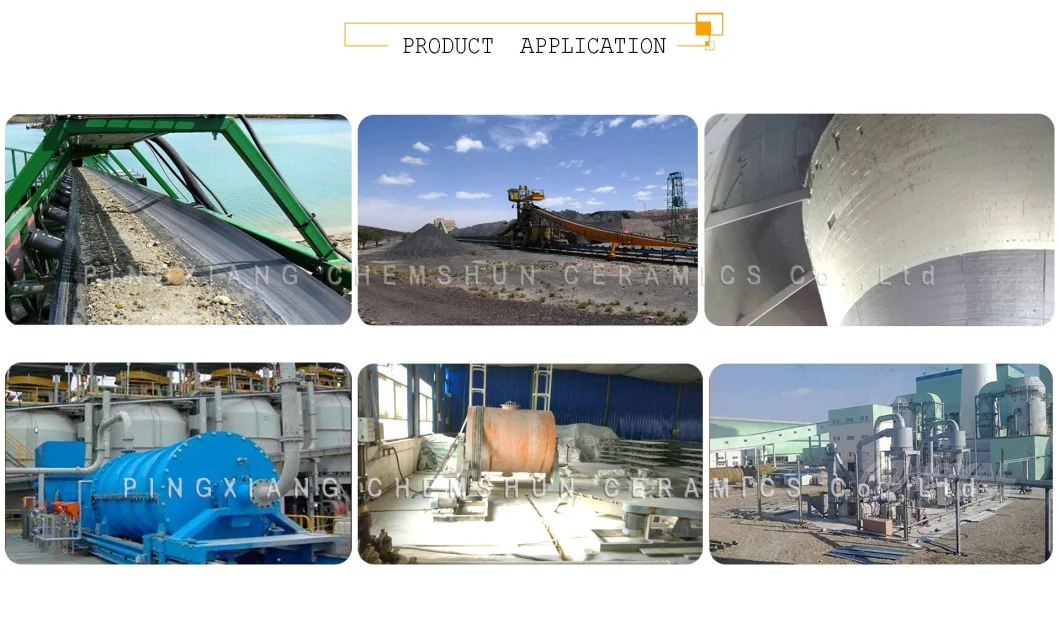

The Tailor-made ceramics had the advantage of low wear,high hardness and impact resistantace,it widely used for the chutes, hoppers, bukers, piplines in the mining, power generation, steel plant, steel plant industries, it make cost effective performance and reduce the maintance cost and down-time for the clients.

Products characters

-- Long lifetime and maintenance free operation

-- No operation interruption or production losses

-- Maximum efficiency of separation

-- superiority of cyclone ceramic tile designed confirmed by computer

Application industry

-- mining industry

-- Cement industry

-- Coal handling industry

-- Steel industry

-- Port industry

-- Power plant

Application in Industries

| Industry | Equipment system | Equipment parts |

| Cement | Pre-blending system for crashing limestone and crude fuel | Chute, bunker, pulley lagging, discharge cone |

| Raw mill system | Feed chute, retaining ring, scraper plate, seal ring, pipeline, bucket guard, cyclone, powder concentrator body, bunker | |

| Cement mill system | Chute, bunker, fan vane wheel, fan casing, cyclone, circular duct, conveyer | |

| Ball mill system | Pulverizer exhauster's body and vane wheel, powder concentrator's body, pulverized coal's pipeline, hot air duct | |

| Sintering system | Inlet/outlet bend, wind value plate, cyclone, chute, dust collector's pipe | |

| Afterheat system | Separator's pipeline and wall | |

| Steel | Raw material feeding system | Hopper, silo |

| Batching system | Mixing bunker, mixing barrel, mixing disk, disk pelletizer | |

| Sintered material transport system | Hopper, silo | |

| Dedusting and Ash discharge system | Dedusting pipeline, bend, y-piece | |

| Coking system | Coke hopper | |

| Medium-speed mill | Cone, separation buffles, outlet pipe, pulverized coal's pipeline, burner cone | |

| Ball mill | Classifier, cyclone separator, bend, powder concentrator's inner shell | |

| Thermal power | Coal handling system | Bucket wheel machine, coal hopper, coal feeder, orifice |

| Ball mill system | Separator's pipe, elbow and cone, coal mill's elbow and straight tube | |

| Medium-speed mill | coal mill body, separation buffles, cone, pipeline, elbow | |

| Fall mill | Pulverized coal's pipeline and elbow | |

| Dedusting system | Dedusting's pipeline and elbow | |

| Ash discharge system | Fan duster's shell, pipeline | |

| Port | Transporting material system | Bucket wheel machine's disk and hopper, transfer point's hopper, unloader's hopper, |

| Smelting | Transporting material system | Measuring hopper, coke hopper, vibrating screen's chute, head valve, Intermediate bin, tail bin |

| Batching system | batch hopper, mixing machine | |

| Burning system | Ash bucket, pump calcine tube, hopper | |

| Dedusting system | Dedusting's pipeline and elbow | |

| Chemical | Transporting material system | Hopper, silo |

| Dedusting system | Dedusting's pipeline and elbow | |

| Processing equipment | Vibromill liner | |

| Coal | Coal handling system | Bucket wheel machine, coal hopper, coal feeder |

| Coal washing system | Hydrocyclone | |

| Mining | Transporting material system | Hopper, silo |

Technical Data Sheet

| S.No. | Attributes | Unit | CHEMSHUN 92 I | CHEMSHUN92 II | CHEMSHUN 95 | CHEMSHUN ZTA |

| 1 | Alumina Content | % | 92 | 92 | 95 | 70-75 |

| ZrO2 | % | 25-30 | ||||

| 2 | Density | g/cc | ≥3.60 | ≥3.60 | >3.65 | ≥4.2 |

| 3 | Color | - | White | White | White | White |

| 4 | Water Absorption | % | <0.01 | <0.01 | 0 | 0 |

| 5 | Flexural Strength | Mpa | 270 | 300 | 320 | 680 |

| 6 | Moh's Density | Grade | 9 | 9 | 9 | 9 |

| 7 | Rock Well Hardness | HRA | 80 | 85 | 87 | 90 |

| 8 | Vickers Hardness(HV5) | Kg/mm2 | 1000 | 1150 | 1200 | 1300 |

| 9 | Fracture Toughness (Min) | MPa.m1/2 | 1000 | 3-4 | 3-4 | 4-5 |

| 10 | Compressive strength | Mpa | 850 | 850 | 870 | 1500 |

| 11 | Thermal Expansion Coefficient (25-1000ºC) | 1x10-6/ºC | 8 | 7.6 | 8.1 | 8.3 |

| 12 | Maximum operation temperature | ºC | 1450 | 1450 | 1500 | 1500 |