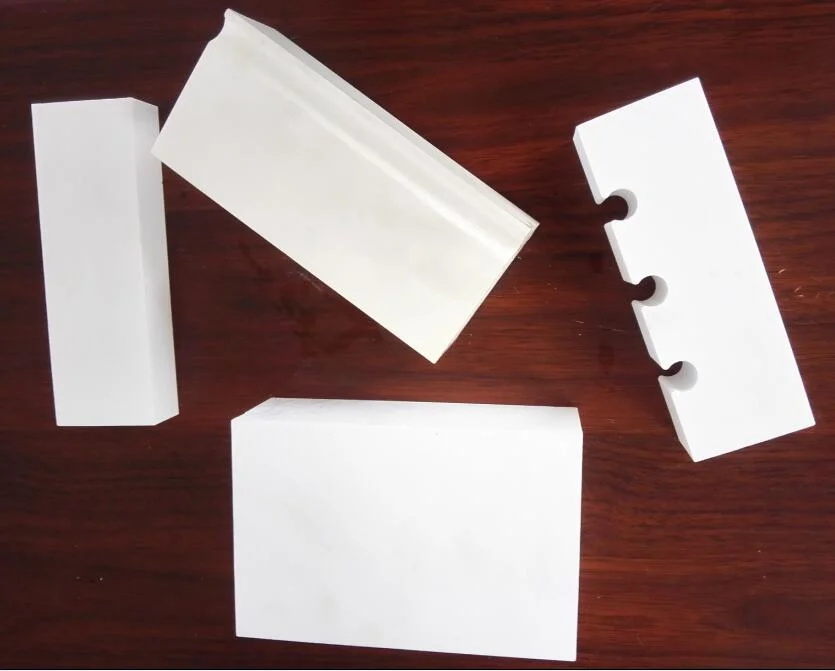

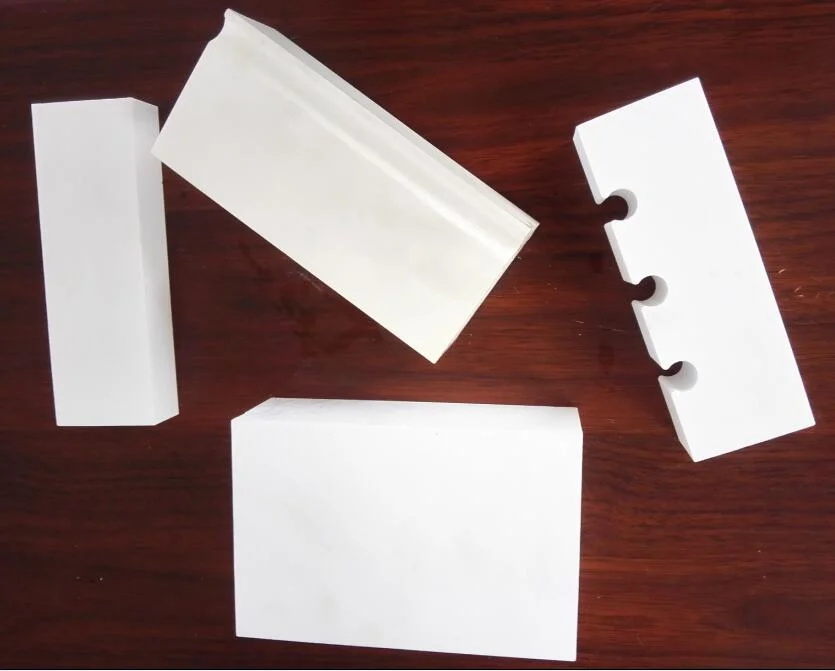

92%/95% High Alumina Ceramic Lining Brick

Alumina Ceramic Tile is of high wear resistance, acid and alkli resistance, effectively prolong the service life of equipment and considered to be the best choice of anti-wearing and anti-corrosion material; Wear resistance of ceramic is 266 times than that of special manganese, 171.5 times to high chrome cast iron; Hardness is much higher than that of wear-resistant steel and stainless steel.

Application: Oil, mining, steel and power industry.

Specification:

Alumina Ceramic Tile is of high wear resistance, acid and alkli resistance, effectively prolong the service life of equipment and considered to be the best choice of anti-wearing and anti-corrosion material; Wear resistance of ceramic is 266 times than that of special manganese, 171.5 times to high chrome cast iron; Hardness is much higher than that of wear-resistant steel and stainless steel.

Application: Oil, mining, steel and power industry.

Specification:

| 1. Alumina ceramic lining plate (Thinkness less than 25mm) | ||||

| Performance Index | 92 Series | 95 Series | 97 Series | 99 Series |

| AL2O3 (%) | >92 | >95 | >97 | >99 |

| Moh's Hardness | 9 | 9 | 9 | 9 |

| Moisture Content (%) | <0.02 | <0.02 | <0.02 | <0.02 |

| Fracture Toughness (n/mm) | 40 | 42 | 44 | 48 |

| Bending Strength (Mpa) | 255 | 275 | 285 | 300 |

| Bulk Density (g/cm3) | >3.63 | >3.68 | >3.73 | >3.83 |

| Item | Length (mm) | Width (mm) | Height (mm) | Remarks |

| 10*10 | 10 | 10 | 3--10 | |

| 17.5*17.5 | 17.5 | 17.5 | 4--10 | |

| 23.7*23.7 | 23.7 | 23.7 | 5--15 | Wear-risisting Plain Brick |

| 50*25 | 50 | 25 | 5--10 | Wear-risisting Plain Brick |

| 50*50 | 50 | 50 | 5--15 | Wear-risisting Plain Brick |

| 100*100 | 100 | 100 | 6.5--15 | Wear-risisting Plain Brick |

| 120*80 | 120 | 80 | 6--20 | Wear-risisting Plain Brick |

| 150*60 | 150 | 60 | 10--25 | Wear-risisting Plain Brick |

| 150*100 | 150 | 100 | 6--25 | Wear-risisting Plain Brick |

| 150*100 | 150 | 100 | 12--50 | Wear-risisting Plain Brick |

| 2. Alumina ceramic bricks (Thinkness more than 40mm) | ||||

| Performance Index | 75 Series | 92 Series | 95 Series | 97 Series |

| AL2O3 (%) | >75 | >92 | >95 | >97 |

| FE2O3 (%) | <0.6 | <0.3 | <0.2 | <0.1 |

| Moh's Hardness | 7.5 | 8 | 9 | 9 |

| Moisture Content (%) | <0.02 | <0.02 | <0.02 | <0.02 |

| Bulk Density (g/cm3) | >3 | >3.63 | >3.68 | >3.73 |

| Wearing Loss (%) | <0.2 | <0.1 | <0.1 | <0.1 |

| Item | Length (mm) | Width (mm) | Height (mm) | |

| End flat brick | 150 | 50 | 40/50/60/70/77/90 | |

| Circle brick | 150 | 50/ 45 | 40/50/60/70/77/90 | |

| Half end flat brick | 75 | 50 | 40/50/60/70/77/90 | |

| Half circle brick | 75 | 50/ 45 | 40/50/60/70/77/90 | |

| Flake brick | 150 | 25/ 22.5 | 40/50/60/70/77/90 | |

| 3. Special alumina ceramic brick for plate | ||||

| Item | Length (mm) | Width 1 (mm) | Height (mm) | |

| 80*50*55 | 55 | 50 | 80 | |

| 110 | 75 | 45/ 41 | 110 | |

| 110 | 37.5 | 45/41 | 110 | |