Hard Track Machining Center (Two-Axis Rail) Metal Hardware Processing CNC Machine

CNC Machine,CNC Machining Center,CNC Lathe,Horizontal Machining Center,Gantry Machining Center,Five-Axis Machining Center,High Speed Driliing and Tapping Machine,Turning-Milling Compound Machine,High Speed Vertical Machining Center,Hard Track Machining Center, Knife Arrangeing Machine, Knife Tower Machine, Knife Tower Tailstock Machine.

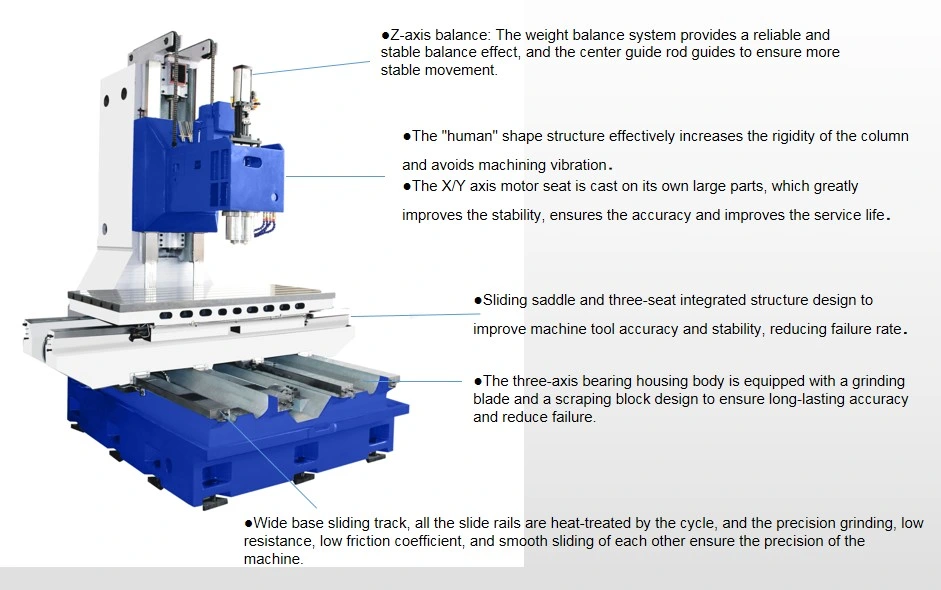

Machine features:

1.The structure adopts modular design and solid closed box structure design. After finite element analysis, overall planning and design, good rigidity and strong cutting ability.

2. All the castings are casted from high-grade Michaela cast iron, which are completely annealed to eliminate residual internal stress and improve the overall stability of the casting. This effectively suppresses machine deformation and vibration caused by cutting force.

3.The X, Y and Z three-axis road adopts square rail and full support design. It can be fully supported by the slide rail in any moving position within the effective stroke. There is no floating phenomenon and smooth movement, ensuring the accuracy of the slide rail, the stability of the cutting and the machinery. life.

4.Be sure to install the guide rails to ensure that the weight does not sway when the Z-axis moves quickly, ensuring accuracy.

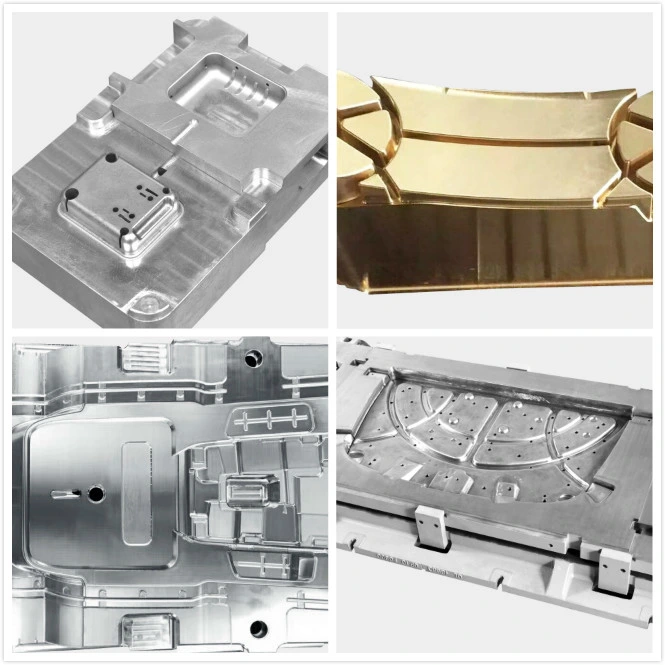

Processing application:

Precision molds, parts, hardware, and automobiles.

Skill number paramteters:

| Machine data / Model number | Units | VMC-650 | VMC-850 | VMC-850C | VMC-1060 | VMC-1150 |

| X-axis travel | mm | 650 | 800 | 800 | 1000 | 1100 |

| Y-axis travel | mm | 400 | 500 | 500 | 600 | 550 |

| Z-axis travel | mm | 480 | 550 | 700 | 600 | 600 |

| Spindel nose to table surface | mm | 80-560 | 105-655 | 110-810 | 180-780 | 150-750 |

| Soindel center to coulumn guard surface distance | mm | 480 | 550 | 575 | 600 | 610 |

| Size of the table (Length×width) | mm | 800×420 | 1050×500 | 1000×530 | 1300×600 | 1200×580 |

| Loading capacity | kg | 600 | 600 | 600 | 800 | 800 |

| Table T-slot(number,size,spacing) | mm | 3-18/135 | 5-18/90 | 5-18/100 | 5-18/120 | 5-18/120 |

| Taper specification | BT40 | BT40 | BT40 | BT40 | BT40 | |

| Spindle maximum speed | rpm/min | 8000/10000 | 8000/10000 | 8000/10000 | 8000 | 8000 |

| Spindle motor | kw | 5.5 | 7.5 | 7.5 | 11 | 11 |

| Three-axis motor(X/Y/Z) | kw | 2.0/2.0/2.0 | 3.0/3.0/3.0 | 3.0/3.0/3.0 | 3.0/3.0/3.0 | 3.0/3.0/3.0 |

| X,Y,Z axis fast moving rate | m/min | 16/16/12 | 16/16/12 | 16/16/12 | 16/16/12 | 14/14/12 |

| Speed of cutting | mm/min | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 |

| Positioning precision | mm | JIS±0.005/300 | JIS±0.005/300 | JIS±0.005/300 | JIS±0.005/300 | JIS±0.005/300 |

| Repositioning precision | mm | JIS±0.003/300 | JIS±0.003/300 | JIS±0.003/300 | JIS±0.003/300 | JIS±0.003/300 |

| Air pressure | kg/cm2 | ≥6 | ≥6 | ≥6 | ≥6 | ≥6 |

| Tool magazine capacity (about) | Handles | 24 | 24 | 24 | 24 | 24 |

| Machine weight(optional) | T | 5 | 5.5 | 6 | 8 | 8 |

| Machine size(Length×width×height) | mm | 2400×2500×2800 | 2600×2850×2800 | 2900×2800×2800 | 3200×2850×2900 | 3400×3000×3000 |

| Control system optional | JAPAN MITSUBISHIM80 / FANUC 0I MF | |||||

| Machine data / Model number | Units | VMC-1270 | VMC-1370 | VMC-1580 | VMC-1690 | VMC-1890 |

| X-axis travel | mm | 1200 | 1300 | 1500 | 1600 | 1800 |

| Y-axis travel | mm | 700 | 700 | 800 | 900 | 900 |

| Z-axis travel | mm | 600 | 650 | 700 | 680 | 680 |

| Spindel nose to table surface | mm | 150-750 | 150-800 | 170-870 | 160-840 | 160-840 |

| Soindel center to coulumn guard surface distance | mm | 785 | 785 | 810 | 950 | 950 |

| Size of the table (Length×width) | mm | 1360×700 | 1400×710 | 1700×800 | 1800×900 | 2000×900 |

| Loading capacity | kg | 1000 | 1000 | 1500 | 1600 | 1600 |

| Table T-slot(number,size,spacing) | mm | 5-18/152.5 | 5-18/152.5 | 5-22/135 | 5-22/165 | 5-22/165 |

| Taper specification | BT50 | BT50 | BT50 | BT50 | BT50 | |

| Spindle maximum speed | rpm/min | 8000 | 8000 | 8000 | 8000 | 8000 |

| Spindle motor | kw | 15 | 15 | 18.5 | 18.5 | 18.5 |

| Three-axis motor(X/Y/Z) | kw | 3.0/3.0/3.0 | 3.0/3.0/3.0 | 4.5/4.5/4.5 | 4.5/4.5/4.5 | 4.5/7.0/4.5 |

| X,Y,Z axis fast moving rate | m/min | 14/14/12 | 14/14/12 | 14/14/12 | 14/14/12 | 14/14/12 |

| Speed of cutting | mm/min | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 |

| Positioning precision | mm | JIS±0.005/300 | JIS±0.005/300 | JIS±0.005/300 | JIS±0.005/300 | JIS±0.005/300 |

| Repositioning precision | mm | JIS±0.003/300 | JIS±0.003/300 | JIS±0.003/300 | JIS±0.003/300 | JIS±0.003/300 |

| Air pressure | kg/cm2 | ≥6 | ≥6 | ≥6 | ≥6 | ≥6 |

| Tool magazine capacity (about) | Handles | 24 | 24 | 24 | 24 | 24 |

| Machine weight(optional) | T | 10 | 11 | 13 | 15 | 16 |

| Machine size(Length×width×height) | mm | 3600×3350×3300 | 3800×3350×3300 | 4800×3200×3400 | 5000×3350×3600 | 5200×3350×3600 |

| Control system optional | JAPAN MITSUBISHIM80 / FANUC 0I MF | |||||

Why choose ShiXingHong CNC Machinery?

1.National high-tech enterprises

2.Guangdong famous brand products

3.Shenzhen famous brand

4.Has 20 years of professional CNC machine tool development and manufacturing experience.

5.To improve customer service system to provide customers with high quality pre-sale, sale, after-sales service and professional technical support is our mission, and provide the overall solution and the whole process of support services.

Company Profile:

Shenzhen Shixinghong Precision Machinery Equipment Co., Ltd. is a comprehensive technology enterprise specializing in the development, manufacture, sales and service of CNC machine tools.The company has a professional technical team dedicated to the field of CNC machine tool manufacturing. It has nearly 20 years of experience in R&D and manufacturing of professional CNC machine tools. With strong technical force, advanced processing equipment and scientific management, the company's machine tools have gained market. Widely recognized.The company has seven major products: five-axis machining center series,

high-speed drilling and tapping machine series, vertical machining center series, horizontal machining center series, gantry machining center series, engraving and milling machine series, CNC lathe series.The high-speed drilling and tapping machine series and the three-axis rail high-speed machining center in the vertical machining center series are our re-launch products. The series of high-speed, high-rigidity, high-performance and high-efficiency features quickly become The preferred machine tool for communications, consumer electronics,medical, LED, automotive, aerospace and other industries.

Corporate headquarters:

Shenzhen shixinghong precision machinery equipment Co.,Ltd is a national high-tech enterprise. The company is the Guangdong famous brand products,Shenzhen famous brand,enterprise is the shenzhen machinery industry association, vice President of enterprise, business association, vice President of enterprises in shenzhen city, Shenzhen polytechc practice base, Hengyang technical college,Zhongshan Torch polytechnic practice base, the enterprise has several national patents, and won the "national AAA grade credit enterprise", "independent innovation demonstration enterprises of guangdong province" and "top ten service unit of guangdong province" "shenzhen machinery industry best employer units" and other honorary titles.

Branch-1

Chongqing Shixinghong Precision Machinery Equipment Co., Ltd. is located in Hechuan District, Beidamen, Chongqing. Since its inception, Chongqing Company has rapidly grown into a representative high-precision CNC machine tool provider in the southwest of the country.

Branch-2

Shenzhen Shixinghong Technology Co., Ltd. is a technology enterprise invested and controlled by Shenzhen Shixinghong Precision Machinery Equipment Co., Ltd. The company is committed to the R&D, design, production and manufacture of CNC machine body and overall appearance sheet metal.

"Creating value for customers, creating opportunities for employees, and creating benefits for the society" is our business philosophy. " Professional service, sincerity and truth" is our service concept, providing customers with high quality with perfect customer service system. Pre-sale, in-sale, after-sales service and professional technical support are our mission.

Sincerely hope to work together with all new and old customers to create a better tomorrow!

company team:

packing and shipping:

Our Suppliers:

Our Clients:

Enterprise honor certificate:

Before and after sales:

Pre-sales technical consulting service:

According to the customer needs tailored report, help customers to select products, process plan analysis, sample cutting, function increase and decrease services.

After-sales service:

(1) installation and debugging: the supplier shall be responsible for free installation and debugging of equipment on the site of the buyer, and provide free on-site training for operation and maintenance personnel.The theoretical training shall not be less than 1 working day, and the practical operation training shall not be less than 3 working days.

(2) technical support: the supplier provides effective technical support, and can optimize the processing procedures and adjust the machine parameters according to the characteristics of processed products.Provide support for the design and application of fixture for processing products.

(3) warranty period: after acceptance of the machine, the supplier shall provide 12 months of free warranty, free parts and services within the warranty period, timely and effective service.

(4) service time commitment: within 10 hours after the supplier receives the machine tool fault report, the after-sales service personnel will arrive at the site to deal with it.

(5) technical support after the warranty period: within 5 years after the warranty period, the supplier shall provide free soft technical consulting services. For example, if the mechanical part of the machine tool fails, the supplier shall provide free soft technical consulting services.

(6) supply of spare parts after the expiration of the warranty: after the expiration of the warranty, the supplier can provide the buyer with comprehensive preferential maintenance parts.And repair parts are provided to the buyer at the purchase cost of the supplier.